Actuation Options

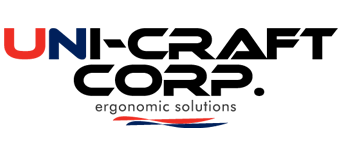

HYDRAULIC

Our hydraulic actuation system includes hydraulic cylinders, hydraulic reservoirs and power unit. Design considerations for specific applications are based on achieving higher lifting capacity, greater travel distance, travel speed, more exact positioning, and firmer, more consistent operation.

Cylinder selection are available from both SAE (Agricultural) and NFPA (Industrial) certified standard cylinder specifications. Cylinders are clevis mounted and available with a re-grease-able spherical bushing to assure proper cylinder alignment. This design minimizes cylinder side loading and extends the cylinder’s life. Specific product needs may require custom cylinder application mounting and related design considerations.

Available for Scissor Lifts, Tilt Tables, Mast Lifts and Upenders.

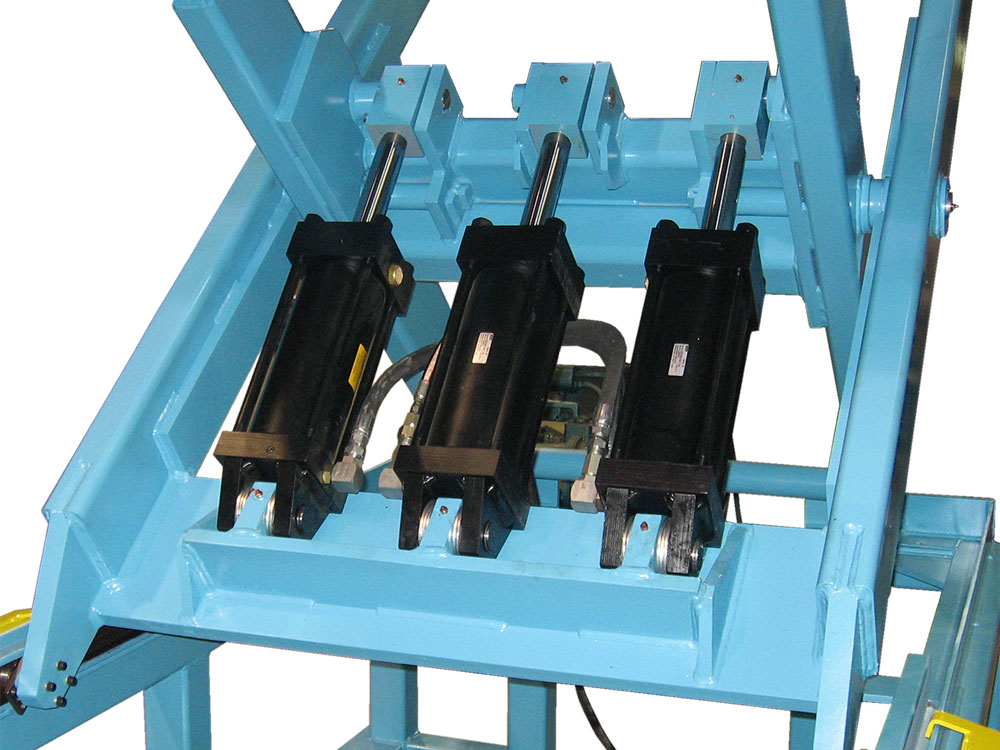

MECHANICAL

Uni-Craft mechanical actuation utilizes a constant force and lifting speed and offers repeatable positioning. Our mechanical option features a long life and low maintenance compared to both hydraulic and pneumatic options. It has a low load on scissor bearings and is completely environmentally friendly.

Linear chain actuation, ball screw and other types of mechanical actuation are available. Linear chain actuation is typically used for high cycle industrial scissor lifts and where precision positioning is required.

Available for Scissor Lifts only. Mechanical Lift Flier

PNEUMATIC

Our pneumatic system utilizes one or more airbags in place of a cylinder and easily connects to simple shop air hook ups. Typically operates with lower travel distances and at a lower cost, eliminates potential of hydraulic leaks, and minimizes electrical requirements for operation in wet conditions.

NOTE: Pneumatic systems may not meet precision positioning needs due to bounciness or spring in the intermediate position between full up and full down.

Available for Scissor Lifts and Tilt Tables.