DESIGN OPTIONS

BEVELED TOE GUARDS

Beveled Toe Guards are required for pit mounted lift tables. The platform is beveled around the perimeter for pit mounting.

FORK CUT OUTS

Fork cut outs allow the scissor lift to be easily fork truck transported. Fork pocket size and location options include single end, multiple end, and all-sides, depending on the specific application configurations.

LEG STIFFENER BARS

A scissor lift’s legs can be designed with a leg stiffener bar for additional support for high travel applications.

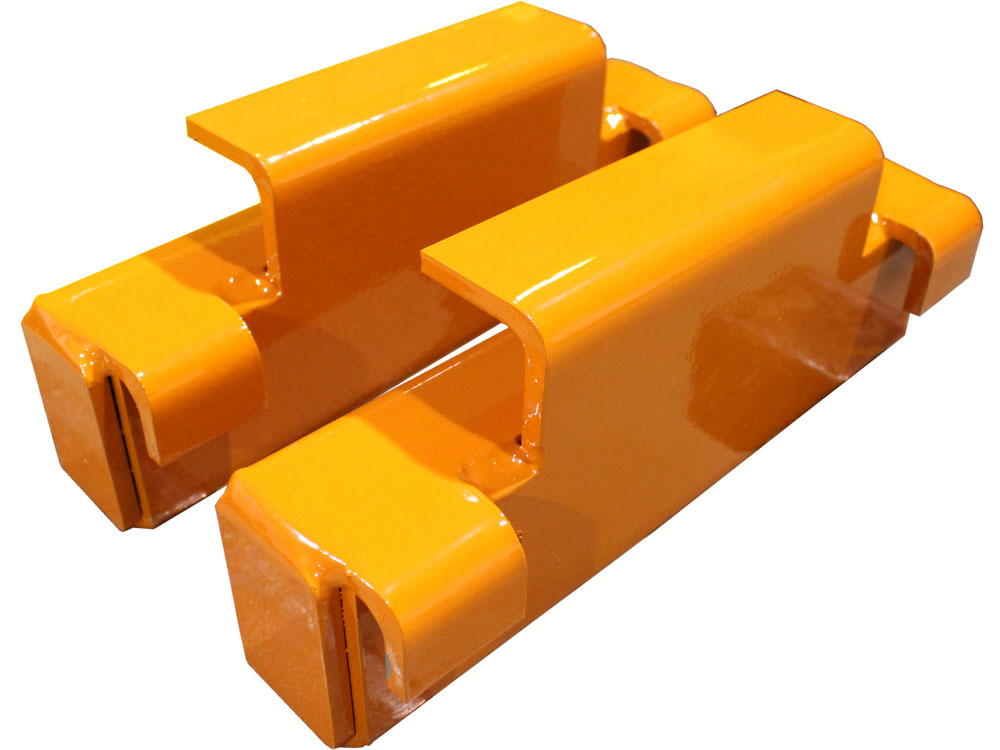

LIFTING BRACKETS

Our lifting brackets are used to lift the unit and position into place only. The lifting brackets are to be removed before use or maintenance of scissor lift.

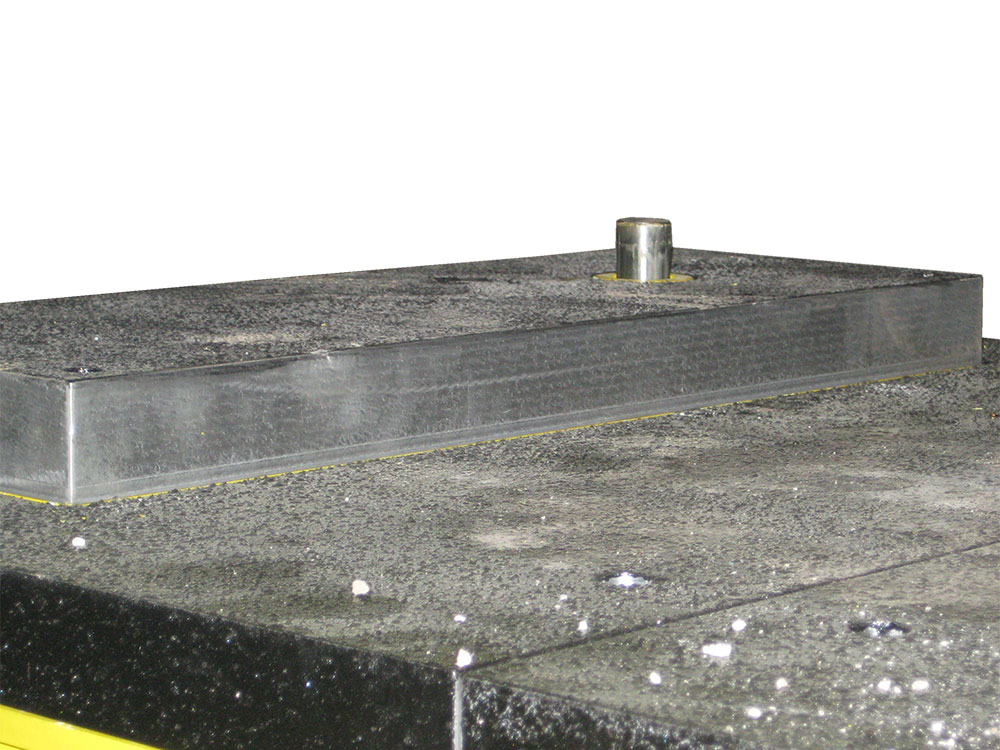

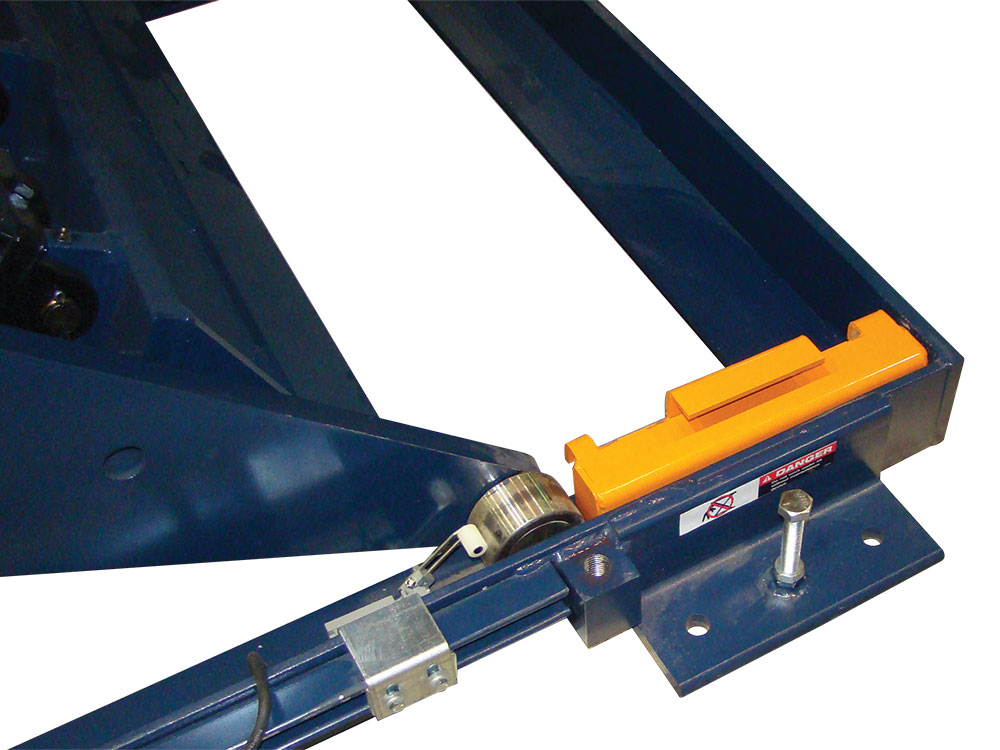

LOAD BARS

Rising load bars are designed to create a smooth transition for loading heavy products. The load bars are a fixed surface and do not transmit loads. Load bars can be mounted to a scissor lift for convenient integration with rollers on conveyor system.

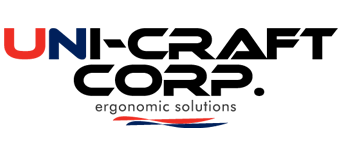

LOCATING PINS

Locating pins pop-up to assist in alignment of equipment that is being loaded onto the lift platform typically for an assembly operation. Designed per application.

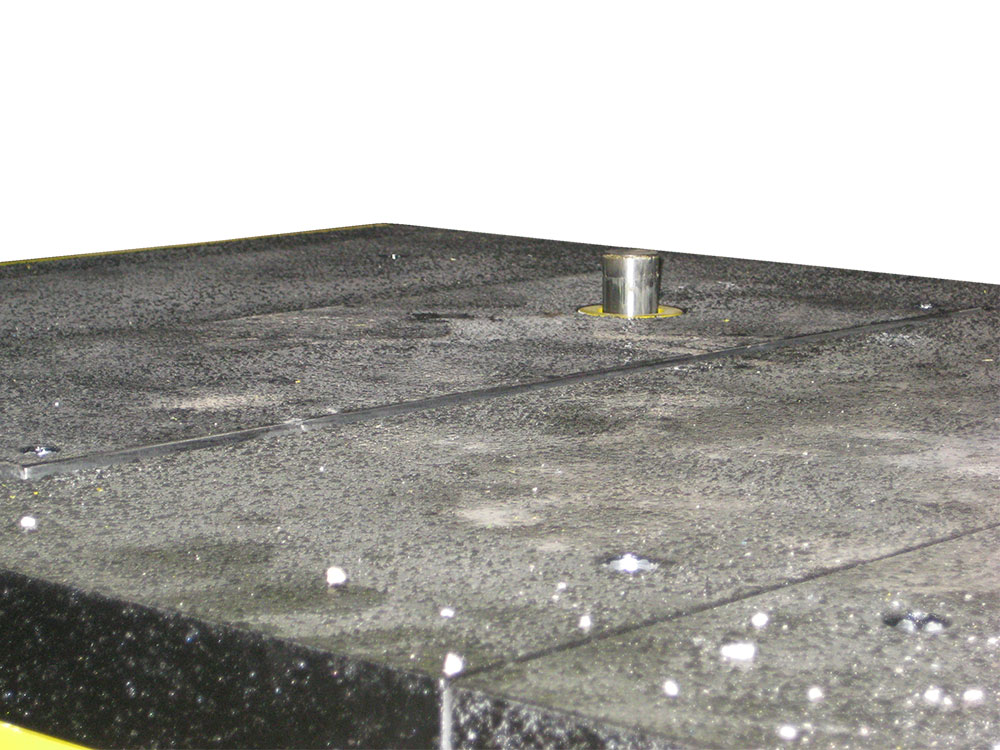

MECHANICALLY RAISED PADS

Pads may be mechanically raised to lift a cart off the tabletop minimizing side force during product loading/unloading, typically needed for assembly applications. Designed per application.

STAINLESS STEEL

All products are available in stainless steel materials for specialty applications or harsh environments, including high wash down needs, food industry applications, submersed use applications, or outdoor operation. See the Stainless Steel Products section for more information.

CUSTOM TABLE TOPS AND PLATFORMS

Custom fixtures. Tie-downs or other fixtures can be integrated onto Scissor Lifts, Tilt Tables, Mast Lifts, and Upenders to secure load. Access panels/ports added to simplify maintenance. Designed per application.

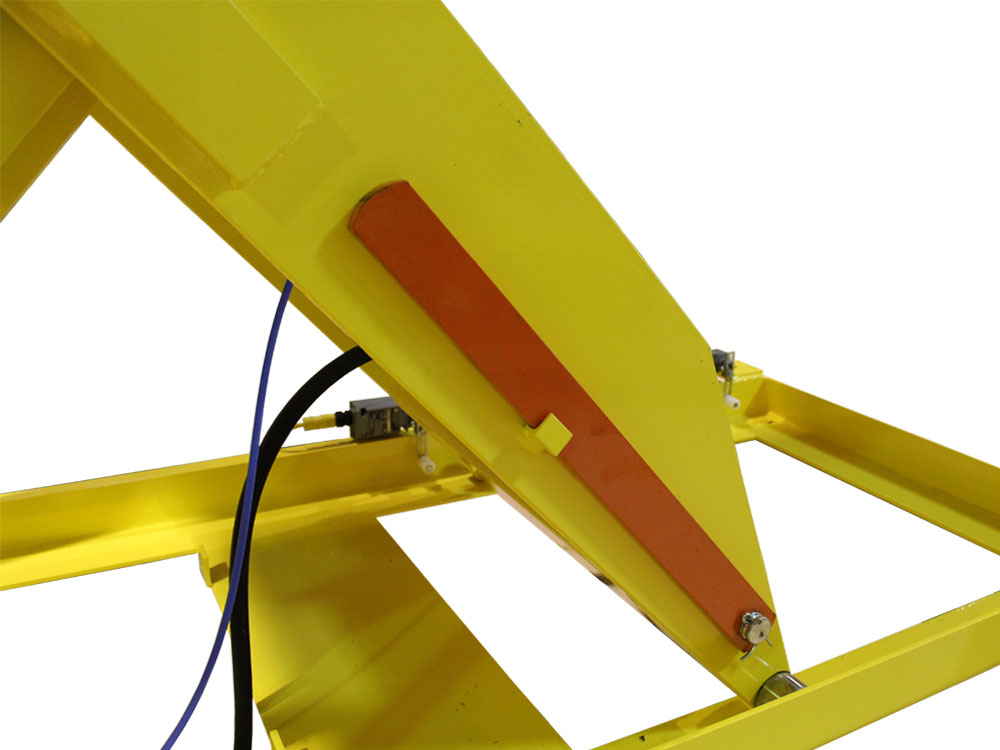

MAINTENANCE BARS

Maintenance bars hold the lift in position, for extended relief on the hydraulic / pneumatic system or while performing maintenance. Provided with every lift table. Design options available for specific application needs, to include pivot, drop in, or pin style.

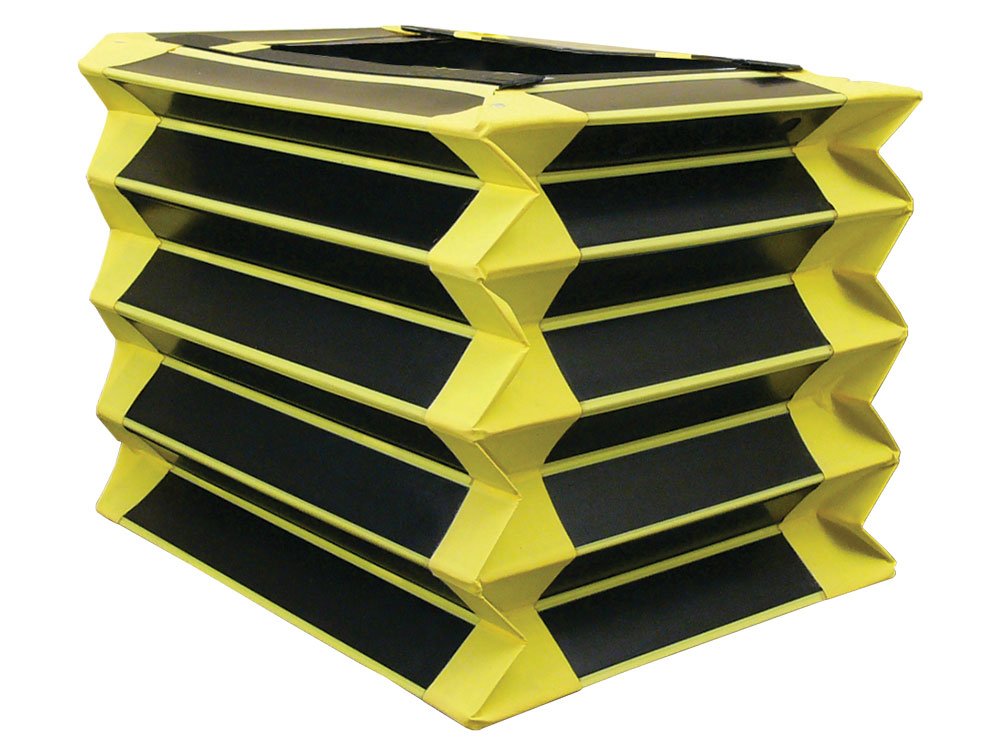

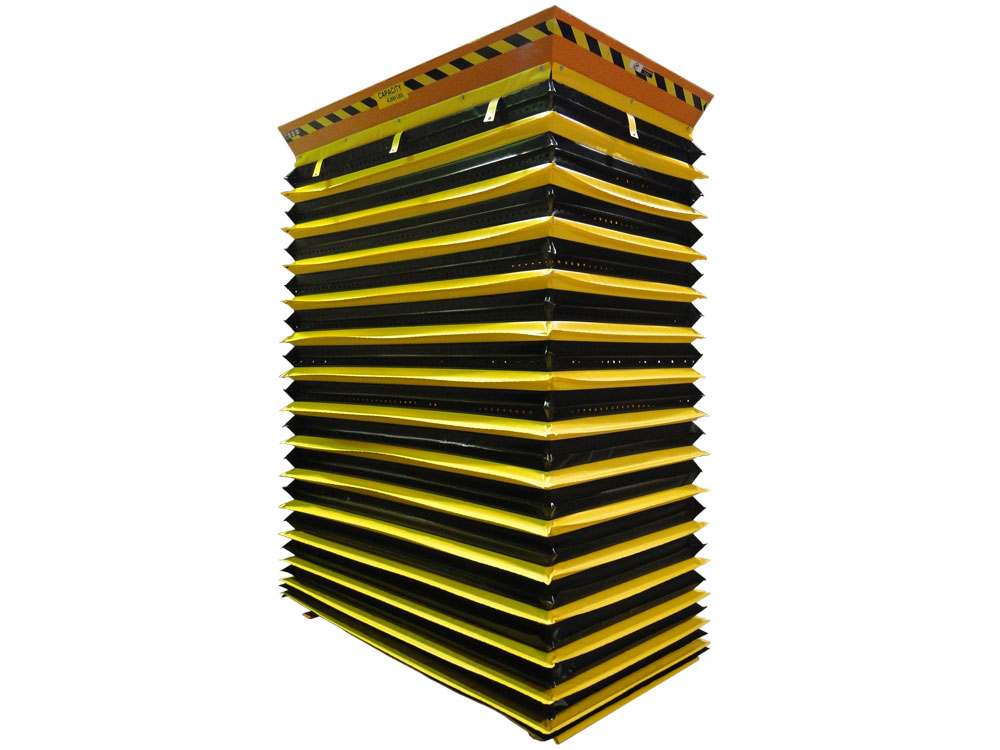

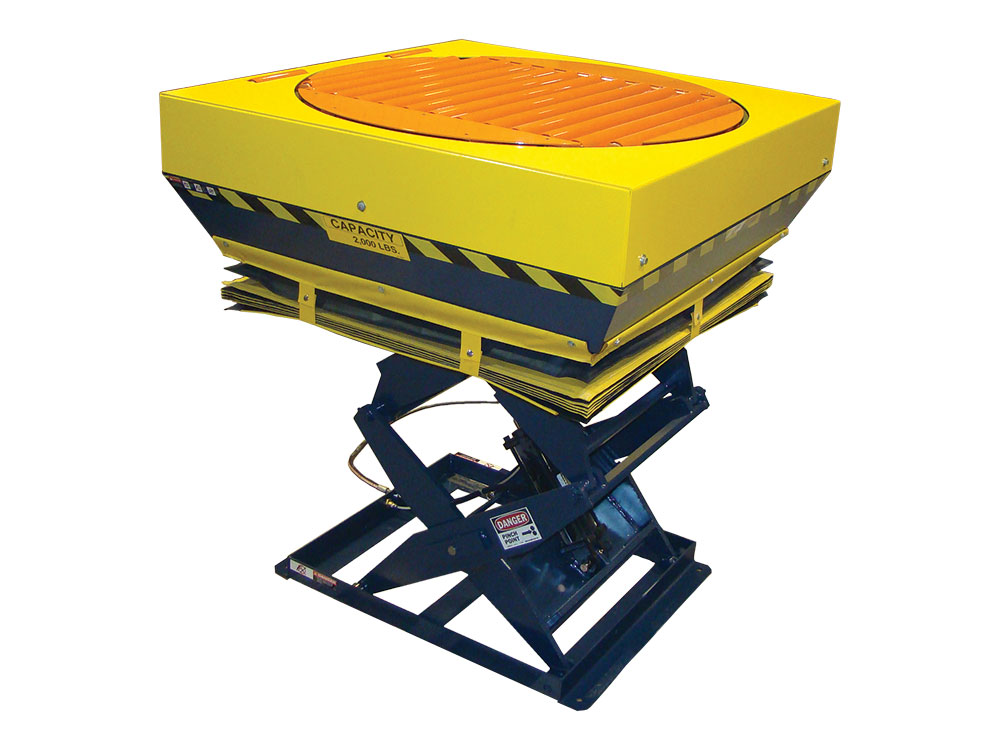

SKIRTING

Standard skirting material is vinyl-coated polyester with support straps for easy maintenance, assuring limited debris accumulation near movable components. The most common color combinations used are yellow and black for a visual deterrent during motion. However, there are numerous other materials and colors available for use.